rose plastic AG has been successfully recertified with Cradle to Cradle Certified® Silver for its protective packaging for transport, storage, and…

Read moreWelcome to rose plastic

Get to know our wide range of high-quality packaging solutions.

As far as we are concerned, there’s nothing more important than your product’s packaging.

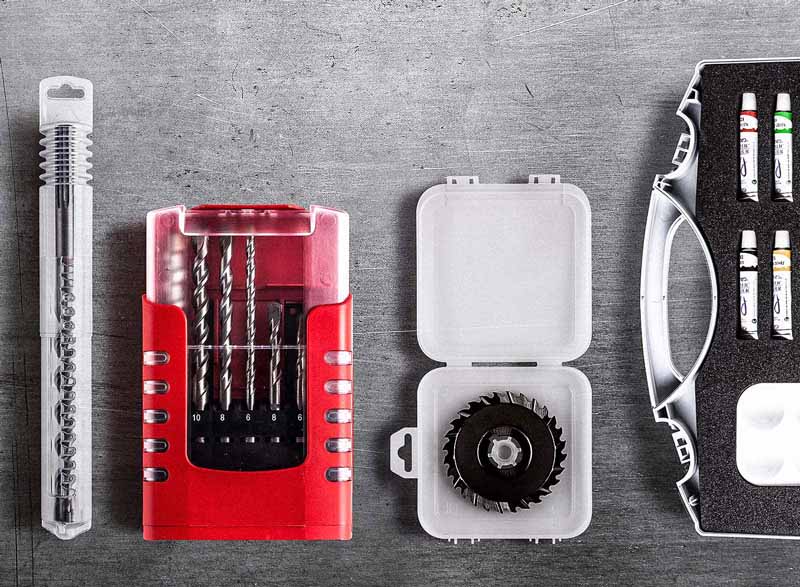

rose plastic is regarded as the world’s No. 1 supplier of high-quality hard plastic packaging for the tooling industry. But many other industries also appreciate the uncompromising quality, precision and reliability of the third-generation owner-managed company. Manufacturers of industrial components, suppliers for DIY stores and the tool trade as well as manufacturers of consumer products and branded goods rely on our efficiency and experience.

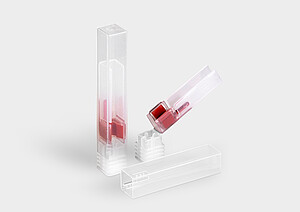

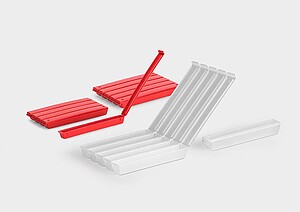

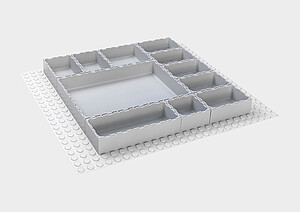

With around 800 employees at 10 locations worldwide, we are where our customers are. For short distances, reliable logistics and sustainable management. Plastic packaging from rose plastic protects your products optimally and combines functionality with sales-promoting product presentation. Our product range comprises more than 4,000 packagings for a wide variety of applications, for example plastic sleeves, boxes, cassettes, cases and transport and storage systems.

rose plastic – family business and global player.

What defines us as a company? What is our heart beating for? How do we look into the future? Here we tell you our story.

By loading this video, you accept YouTube's privacy policy. You can find more information here.

Please feel free to have a look at us. Get to know our versatile packaging and our markets. And last but not least, the people who make rose plastic so successful.

In a world that is increasingly confronting the challenges of sustainability, the use of recycled material in the plastic packaging industry is…

Read moreIt’s already been “around the block” a few times. Nevertheless, we wanted to showcase our popular BlockPack once again with a new video. We think the…

Read moreAt a time when environmental protection is increasingly in the spotlight, we must all play our part in finding and implementing sustainable solutions.…

Read moreAnyone familiar with the InsertBox from rose plastic knows how well it protects high-quality indexable inserts from damage. Our InsertClickBox now…

Read moreSustainability is a top priority for us. So much so, in fact, that we are now even adding a portion of recyclate to our small protective caps.…

Read moreSustainability and plastic, that is not a contradiction. With packaging made of recycled plastic rose plastic takes responsibility, saves resources…

Read moreStylish, functional, robust, practical, secure: Our case solutions may be many things, but they are certainly not boring. On the contrary, no matter…

Read morerose plastic AG has been awarded the “PRS Green Label” by the PRS organization based in Eindhoven/NL. It is committed to recycling sustainably…

Read moreNew life through high-quality recycling

Plastic packaging and sustainability is no contradiction: if plastic is correctly separated after use, it is ideal for recycling. Whether it is a yogurt cup, shampoo bottle, or another type of household plastic waste. Through high-quality recycling, the old plastic can finally be brought back to life. This is the basis for the new packaging products from rose plastic. These are now available made from recycled material.

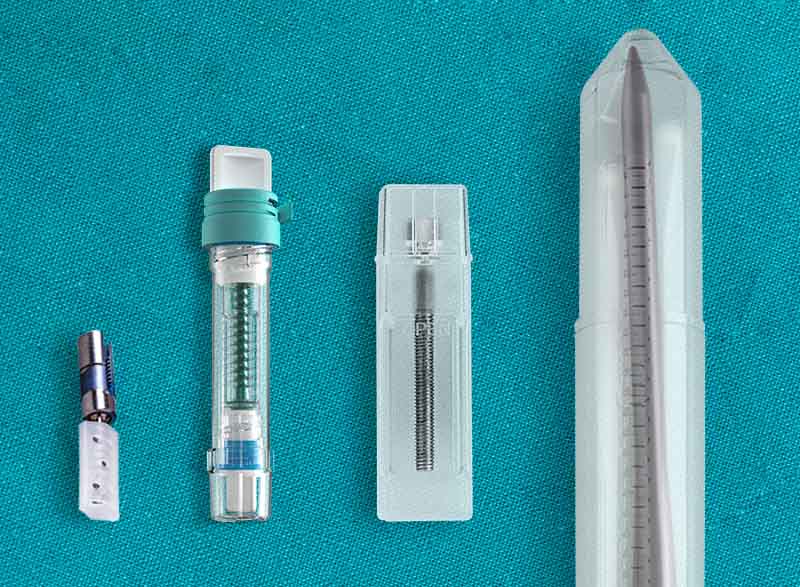

Packaging solutions for your products from the fields of medical device, dental, healthcare and laboratory can be found in a large selection at rose plastic medical packaging.